Heat Transfer and Thermal Bridging Explained

To properly understand how thermal bridging works, you need to understand heat transfer. If you want to know more, and you haven’t yet read our blog How Does Low-E Insulation Work? you can read it opposite here.

We have put this blog together to help you understand some basics about heat transfer and to answer some of our most FAQs we get asked to explain the importance of thermal bridging and how heat transfer actually works.

Common Thermal Bridging and Heat Transfer Questions

Some of the most common questions we get asked about Low-E Insulation, thermal bridging and heat transfer are;

- How does heat transfer work?

- Can Low-E insulate against cold?

- What is thermal bridging?

- How can I reduce thermal bridging?

- What is the difference between cross battening and parallel battening?

How does heat transfer work?

Heat always displaces cold

One of the first rules of thermal dynamics is that heat will always displace cold, never the other way around.

Heat ‘escapes’ from a hot cup of coffee and the coffee becomes cold, but cold never ‘escapes’ from a cold drink. Instead the warm air around the drink is drawn towards the colder surface until an equilibrium is reached.

Consider your freezer at home. You aren’t stopping the cold from getting out. What you are doing, is stopping the warmth outside from getting into the colder space inside.

Another way to explain this is to consider things on smaller scale. The warmer an object is the faster the molecules in it are moving. The molecules in boiling water for example, are moving very fast but molecules don’t like running around would naturally prefer to move more slowly, so if they can move somewhere cooler and slow down, they will.

Now that you are understanding that heat is always looking to displace cold, we can start to explain thermal bridging.

What is Thermal Bridging?

The path of least resistance

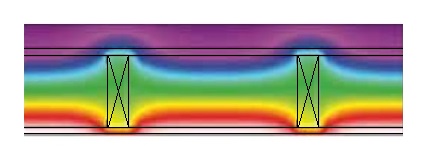

Thermal bridging, or a thermal ‘bridge’, is when the warmer side of an insulated system is in direct contact to the colder side by a material (or materials) that are more conductive than the materials around them.

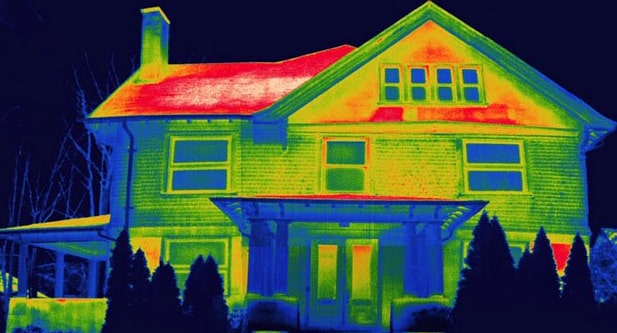

The diagram presented here shows a section of an insulated timber frame wall. Insulation is fitted between the timbers of the frame and this gives a very good insulation value.

However, you will notice that timber frame itself has several areas where the internal (warm) side of the wall and the external (cold) side of the wall are connected by the timber ONLY and are un-insulated. These areas are called ‘thermal bridges’ and although these are only small areas in the wall, the combination of them all can result in a fair amount of heat loss.

What you also need to consider is that heat will take the path of least resistance. When heat is trying to escape from the building it will automatically be drawn towards the thermal bridges rather than trying to escape through the less conductive insulation on either side.

So, heat will travel from the surrounding areas of the wall on the internal side towards any thermal bridges which present the path of least resistance.

You can see how this is highlighted in the thermal imaging.

How Can I Reduce Thermal Bridging?

Unbroken layer of insulation

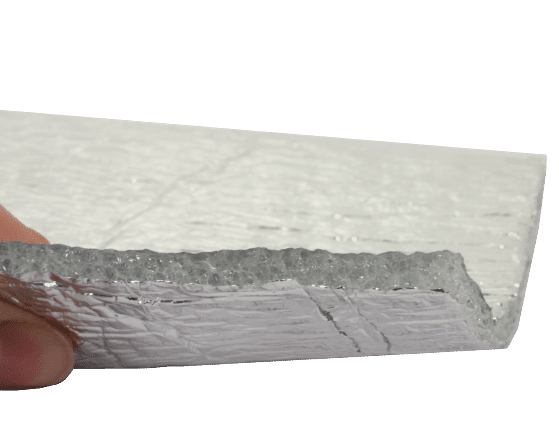

Installing a layer of Low-E Insulation over the surface of any wall, floor, roof or ceiling is a very simple way to reduce thermal bridging. Because Low-E is only 5.5mm thick it can easily be installed in one piece, taping and joining the rolls together where needed.

This creates an unbroken piece of insulation over an entire area, rather than cutting the insulation to fit between timbers, leaving gaps and creating thermal bridges.

What is the Difference Between Cross Battening and Parallel Battening?

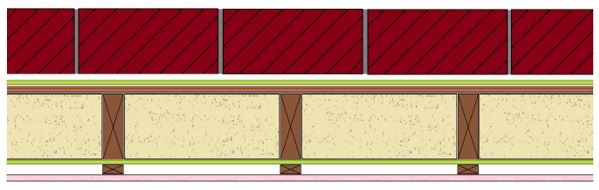

The most common method for installing Low-E Insulation is to install it with a (2” x 1”) counter batten. The batten can be installed parallel with the timber frame or cross battened.

Parrallel Battening

Low-E insulation has a crush resistance of 72 PSI so it will not collapse completely under the pressure of battening. However, parallel battening does create a larger area of thermal bridging as the timber batten siting on top of the entire length of the timber frame.

Cross Battening

The most popular method for installing Low-E Insulation is to install it with a cross batten. Cross battening is more efficient as it reduces the areas of thermal bridging.

The difference between these options might seem small but parallel battening could account for 12.5% thermal bridging in a timber frame wall, while cross battening could reduce the area of thermal bridging down to 8.33%.

To put that in terms of U-value and R-values The parallel battening would come out with a U-value or 0.21 W/(m2K) (R-value 4.71m2K/W) while if cross battened, the same wall (made with the same materials) would come out 0.20 W/(m2K) (R-value 4.95 (m2K/W).

So, now you understand the principles of heat transfer and thermal bridging. Hopefully it will help you plan and design you next project.

Recent Comments