How Does Low-E Reflective Insulation Work?

We have put this blog together to help answer some of our most frequently asked questions about how reflective insulation and Low-E Insulation works. If you have any questions about using Low-E in a specific application, please get in touch.

Low-E Reflective Insulation is a very simple, very effective material that is it also easy to work with, made from recycled material, safe to handle, has no airborne fibres and is class 1 fire rated.

Low-E Insulation is not designed to replace all other insulation materials on the market. It is designed to reduce life cycle running costs, provide moisture protection, stops draughts, deaden sound but most importantly, to tackle issues which are usually left unaddressed by traditional bulkier insulation products.

If you would like to learn more about Low-E Insulation and see it compares to other reflective insulations and traditional insulation you can read our blog opposite

Common Questions On How Low-E Insulation Works

Some of the most common questions we get asked are

- What is the recycled material in Low-E Insulation?

- What is Low-E Insulations GWP?

- What are the environmental benefits of using Low-E Insulation?

- What about the cost of transporting Low-E by sea?

- How have you calculated the carbon footprint of Low-E Insulation?

- Is any insulation Carbon Negative?

How does foil insulation work?

The first questions we need to ask is – Why Do We Insulate?

Most people believe that we simply insulate to keep warm. In fact, we insulate for many reasons including comfort

- Airtightness

- Moisture control

- Thermal efficiency

- Reduce running costs

There is more to insulation than just retaining heat but before we talk about thermal efficiency, we first need to understand the basics of heat flow and we need to define three basic mechanisms of heat transfer

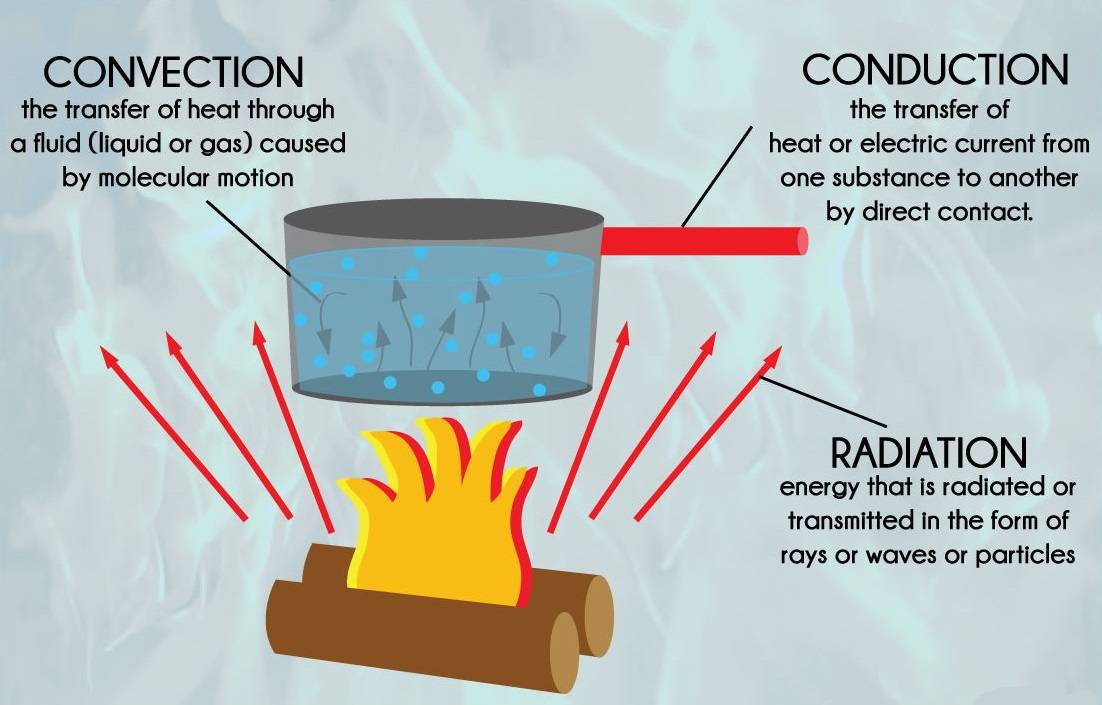

Heat is transferred by 3 different means.

Conduction – is heat travels through a solid object, or between two objects that are in direct contact. You will feel conduction taking place if you leave a spoon in a hot cup of tea.

Convection – is heat that is transferred by air currents. You can see convective heat rise from a hairdryer, or from the surface of a hot road.

Radiation – is transferred by electromagnetic waves which can pass through anything. Radiant Heat is produced by the Sun and heats the earth, but it is also produced by radiators in your home, and even your body radiates heat. When radiant heat meets a surface, it is either reflected away, or it is absorbed. Once absorbed it can be conducted or re-radiated on the other side.

“Radiation is the primary mode of all heat transfer. The other two modes… come into play only as they interfere with the primary mode.”

Pelanne, Senior Research Specialist for Johns Manville (Energy Design Update, Feb. 93)

The most common ‘traditional’ insulation materials work by slowing down convection and conductive heat flow, but they do little to tackle radiant heat. To understand why that is, we need to understand how we measure an insulation materials ability to insulate. And we need to understand 3 thermal values; an R-value, and U-value and an E-value.

R-value – is a measure a material’s ability to resistance conduction heat flow. The higher the number, the better its ability to resist conductive heat flow. The thermal properties of insulation products are usually stated in R-values.

U-value – is a measure of a material’s ability to conduct heat. The lower the number the better its ability to resist conductive heat flow. The thermal performance of windows, doors and buildings is commonly stated in U-values. You can calculate a U-value from an R-value (U-value = 1/R-value)

E-value – is a measure of Emissivity. Emissivity is the ability to emit or transfer radiant heat through a surface. The surface of every material has an Emissivity value.

What is Emissivity?

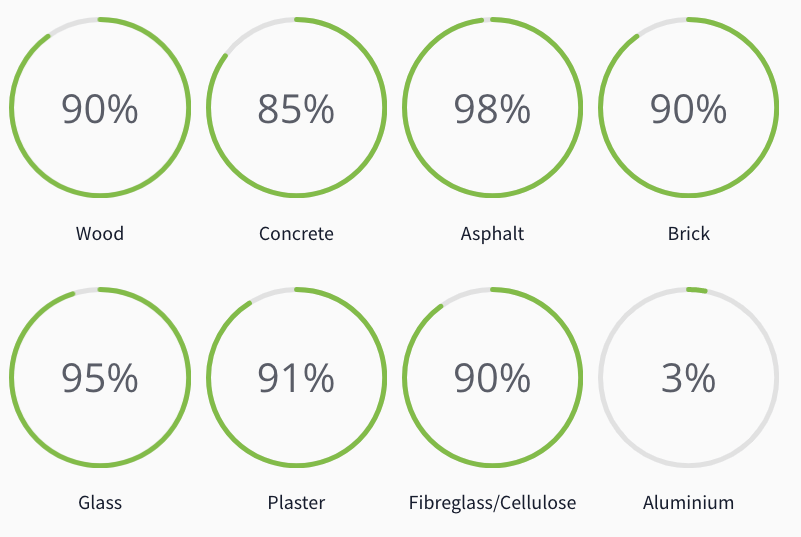

You may have heard of low E glass in windows. Well the ‘E’ stands for Emissivity and Low-E Insulation works the same way. Everything has an emissivity value. Here are the emissivity values for a list of building materials:

Most common building material have high emissivity values. Plaster and fibreglass have an emissivity value of approx. 0.90. That means that 90% of radiant heat that meets the surface of these materials will be absorbed and pass through the material.

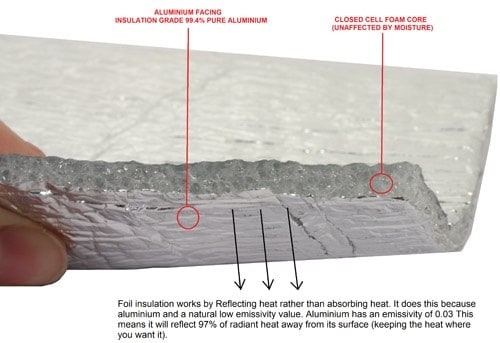

Aluminium on the other hand has a very low natural emissivity value of 0.03. This means that only 3% of radiant heat to meets an aluminium surface will pass through it. Or another way to look at it, is that 97% of heat will be reflected back to the source.

As long as a product is made from aluminium and has a true low emissivity value it will reflect radiant heat. To understand why aluminium is important you can read aluminium -v- mylar here…

Why is foil insulation different from traditional insulation?

Traditional insulations work by slowing down conductive heat transfer, but they need to absorb heat in order to work. For years, to improve insulation standards we have just added more and more of the same traditional insulation materials. We thought that was all we could do.

That suited the manufacturers of those products who continually lobby the government to improve standard so they can sell more product. But regardless of how high an R-value is, if an insulation system doesn’t also have a low – E value it has no ability to reflect radiant energy. Very high R-values don’t stop heat transfer, they simply slow it down.

R-values -v- E-values

You cannot ignore the need for good R-values, but by addressing the R-values alone, you leave a large percentage of heat transfer being ignored.

It is wort noting that; although all three forms of heat transfer take place out of a building, 100% of the solar gain is radiant heat. When you consider how hard air conditioning units work during summer months to deal with solar gain, it might also be worth asked. Why Building Regulations don’t address solar gain in insulation standards?

Does foil insulation have an R-value?

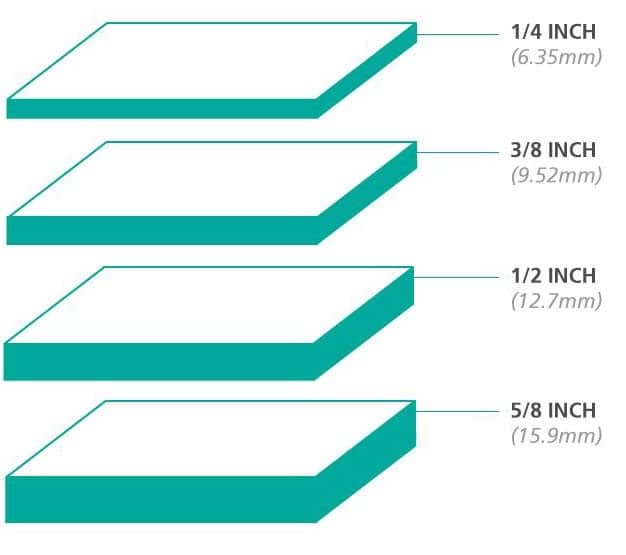

Foil insulation achieves an R-value in two ways. The first is through the resistance of the core of the material and the second is through the air layer adjacent to the foil surface.

Reflective materials that do not have separating layer or Core, usually come under the title Radiant Barriers.

How do Airspaces work?

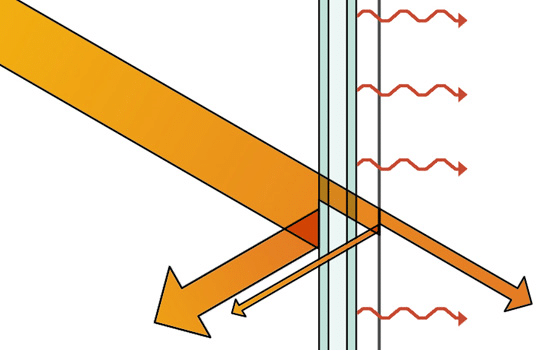

The easiest way of explaining how low emissivity airspaces work is to use a double-glazed window as an example. The two pieces of glass in a double-glazed window do nothing on their own, but when the layers of glass are separated by an airspace, it is the airspace that becomes efficient.

However, when there is a low emissivity surface (pure aluminium) on one side of the airspace, the airspace becomes nearly 5 times more efficient than the one in a double-glazed window.

Are Airspaces important?

Reflective insulation can work without an airspace but to declare an R-value the airspace must be present. Airspaces can be formed in numerous ways and can be as small as a 6mm, but they are most efficient between 6mm – 20mm.

The easiest way of explaining how low emissivity airspaces work is to use a double-glazed window as an example. The two pieces of glass in a double-glazed window do nothing on their own, but when the layers of glass are separated by an airspace, it is the airspace that becomes efficient.

However, when there is a low emissivity surface (pure aluminium) on one side of the airspace, the airspace becomes nearly 5 times more efficient than the one in a double-glazed window.

Claiming an R-value

Some foil insulation companies simply claim a single R-value for their product. This is not correct!

The R-value of ANY reflective foil insulation will change depending on the size and orientation of the airspace beside the foil surface.

Summary – How Low-E Reflective Insulation works

Heat flows from warmer objects, airspaces, or surfaces to cooler ones, until there is no longer a temperature difference. In your home, this means that in winter, heat flows directly from all heated living spaces to adjacent unheated attics, garages, basements, and anywhere else that is cooler than your heated area.

Heat flow can also move indirectly through ceilings, walls, and floors. The opposite is true in the summer, where heat is transferred from outside into your cooler home.

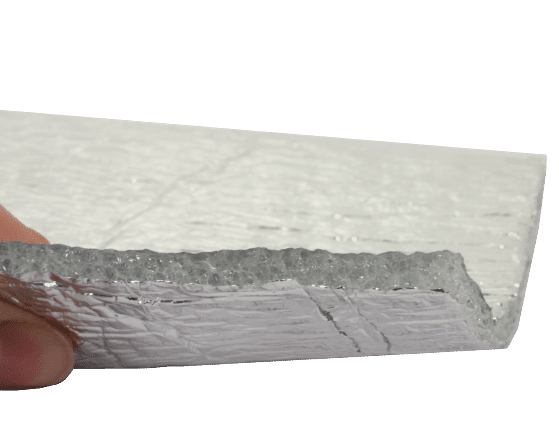

The composition of Low-E Insulation with its recycled closed cell foam core means that it can successfully tackle all three forms of heat loss. The core provides a thermal break to reduce and stop conduction and convection. While the 99.4% pure aluminium low emissivity surface reflects 97% of radiant heat back to the source.

Low-E Insulation is not designed to replace all other insulation materials on the market. It is designed to reduce life cycle running costs, provide moisture protection, stops draughts, deaden sound but most importantly, to tackle issues which are usually left unaddressed by traditional bulkier insulation products.

You can read about the important of Air Tightness and Moisture Control here…

Recent Comments